Travis Casper Email

Sales and Rentals . Ozzie's Pipeline Padder

Phoenix, AZ

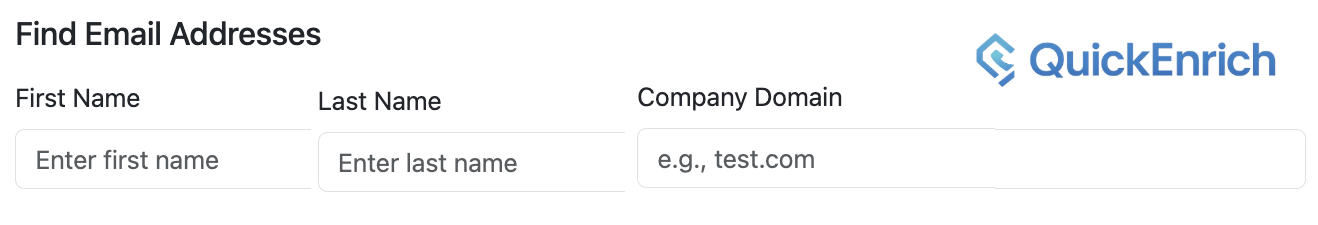

LocationPrimary Email

How to contact Travis Casper

Join and see Travis's contact info for free!Phone

Current Roles

Employees:

51Revenue:

$16.2MAbout

Ozzie’s Pipeline Padder, Inc. (“Ozzie’sâ€) invented pipeline padding and continues to be the industry leader, globally. We bring over 25 years of experience in backfill separation (“paddingâ€) to the pipeline industry. Ozzie’s offers a full range of versatile and durable padding solutions designed and engineered to meet almost any padding requirement. Our padding machines are backed up by a team of highly qualified pipeline equipment specialists who are committed to providing our customers with the optimal and most cost effective padding solutions. What We Do: Pipeline padding–large and small mainline pipeline padding solutions Alternative energy–underground distribution and collection lines backfill for solar and wind farm projects Screening services–beach cleaning and site clean-ups Enhanced oil recovery–CO2 injection line backfill Utility–commercial and residential utility construction backfill Custom screening solutions Our Equipment OPP-300: Our largest and most productive cross-country padding machine. Designed for the toughest, large-scale mainline pipeline projects. Power: 440 HP (328 kW) Processing Capability: 778 yd3/hr (595 m3/hr) OPP-200: Our mid-sized mainline cross-country padding machine. Engineered to easily handle medium sized mainline pipeline projects. Power: 335 HP (250 kW) Processing Capability: 444 yd3/hr (339 m3/hr) OMS-360: Our newest excavator style padding machine. Designed to handle medium diameter mainline pipeline projects, tie-ins, bell-holes, and padding on difficult terrain. Power: 218 HP (160 kW) Processing Capability: 300 yd3/hr (229 m3/hr) Mini-Padder: Ideal for small inch pipeline and distribution, as well as back filling wind, solar farm, and underground cable. Power: 175 HP (129 kW) Processing Capability: 130 yd3/hr (50 m3/hr) Micro-Padder: Our smallest, most compact padding machine. Ideal for wind, solar farms, utility back fill work and telecom. Engine Power: 100 HP (74.6 kW) Process Capacity: 80 yrd3/hr (61 m3/hr)Ozzie's Pipeline Padder Address

7102 W Sherman StPhoenix, AZ

United States