John Robinson Email

Regional Account Manager . NFM Welding Engineers

Massillon, OH

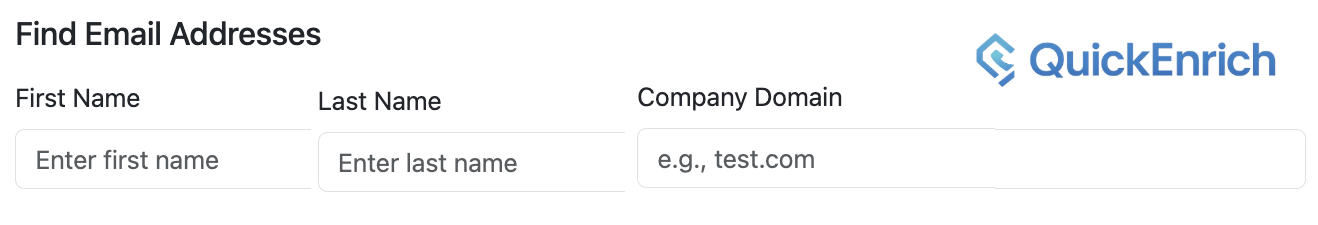

LocationPrimary Email

How to contact John Robinson

Join and see John's contact info for free!Current Roles

Employees:

80Revenue:

$35MAbout

NFM is a leading global OEM for rubber and plastic extrusion systems. NFM offers full turnkey extrusion systems, featuring custom integrated controls for all auxiliary equipment. NFM also offers global field service and full rebuilding of any extruder OEM's equipment including barrels, feedscrews, feed sections, power feed roll and door assemblies, and gearboxes. Technologies and applications include: TEM Series - Co-Rotating Intermeshing Twin Screw Extruders - Polymer Compounding - Hot Melt Adhesive Compounding - Devolatilization - Direct Extrusion - Reactive Extrusion - Synthetic Rubber Compounding - Recycling WE Series - Counter-Rotating Non-Intermeshing Twin Screw Extruders - Devolatilization - Reactive Processing - Latex Coagulation of Thermoplastics and Elastomers - Synthetic Rubber Finishing - Hot Melt Adhesive Compounding HSX Series - Single-Screw Extruders for Plastics - Sheet & Film - Profile Extrusion - Recycling HRX Series - Single-Screw Extruders for Rubber (Pin-Barrel and Smooth Bore) - Tire & Tread Extrusion - Belting (Conveyor, automotive, etc.) - Seal Systems (Automotive, Window & Door, etc.) - Hose - Wire & Cable Silcure Series - Single-Screw Extruders for Silicone Extrusion - Medical Tubing - Seal Systems (Automotive, Window & Door, etc.) - Wire Insulation - Industrial Tubing - High-Temperature Gas HoseNFM Welding Engineers Address

577 Oberlin Road S.W.Massillon, OH

United States